○ high energy saving

Energy saving, environmental protection and no pollution, using DC drive, ultra-low energy consumption, electro-optical power conversion is close to 100%, the same lighting effect than the traditional light source energy saving more than 80%.

○Long service life

LEDs are known as lights that never go out and have a long service life.

The use of solid cold light lamp, epoxy resin packaging, shielding the traditional lighting filament light is easy to burn, thermal precipitation, light decay and other shortcomings, the service life can reach 50,000 to 100,000 hours.

○environmental protection

The spectrum of LED does not have ultraviolet and infrared, low heat, no stroboscopic, no radiation, no mercury elements pollution-free.

○ Low maintenance cost

LED lighting has a small power to achieve 5 times the power of lighting effect, its supporting less investment.

No rectifier, long service life can be repaired, and the follow-up maintenance is much lower than traditional lamps.

Brilliant elevator energy feedback technology is to use the elevator in the process of up run or down run potential energy unbalance principle, by automatically detecting dc bus voltage of the inverter, the DC voltage of the DC link of the inverter is inverted into the AC voltage with the same frequency and phase as the power grid voltage, after multiple filter to get "green elevator" no "pollution" of power grids, not only make the elevator energy consumption is decreased, also supply other electrical equipment in the same power system, and the electricity returned to the grid can reach more than 97% of the power generation energy, and energy savings of 50% can be achieved

○ Overall optimal allocation

When the call to the landing is input, the Group control management software will carry out high-speed calculation on the information, and make the most reasonable distribution of elevator operation after analysis and evaluation. All elevators will be ready for the call to the floor and run in accordance with the best scheme.

In accordance with the principle of minimizing the elevator running distance, energy-saving operation is realized. In a specific period of time, the group control management software analyzes the call instruction of each floor and allocates the Intellectual operation of the elevator, so as to shorten the overall running distance of the elevator.

○ Destination floor control system

The destination floor group controller realizes the group control of elevators by calculating the arrival floor of passengers. Through an Intellectual controller, the service area of elevators in the group is dynamically distributed, and the response time to passengers is the shortest.

Its advantages are: reduce the crowded situation when passengers take the elevator;

Improve the handling capacity of the elevator;

Shorten the operation cycle and service time;

Reduce the number of elevator starts, save energy.

○ Wrong instructions in the Car are cancelled (standard configuration)

If the instruction button is operated incorrectly, the instruction can be cancelled by pressing the error layer button twice continuously.

○Voice announcement system

When the elevator reaches a certain floor, it prompts the information of the floor where the passenger car is located.

○Power failure emergency leveling device

When the external power supply fails, the backup power supply provides the control power, and the nearest flat layer allows the passengers to leave safely.

○Video supervisory electronic camera

Cameras are installed in the car to monitor the situation in the car in real time and find the occurrence of accidents as soon as possible.

○ Load 1000kg~1600kg, elevator speed 3.0m/s~4.0m/s, 2:1;

○ Adopting rewinding scheme to meet the traction requirements of high-speed ladder;

○ The use of QT700 material, traction wheel long life;

○ Adopt double support structure, mechanical bearing capacity up to 12000 kg;

○ Small size, light weight, cost-effective.

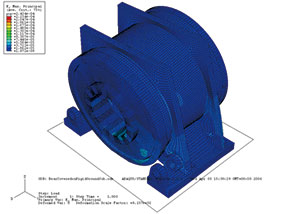

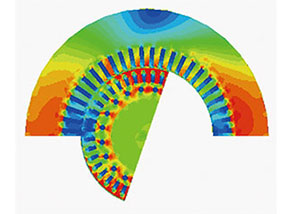

○ Using professional software for electromagnetic design, and the application of finite element magnetic field analysis, to ensure the safe operation of the motor.

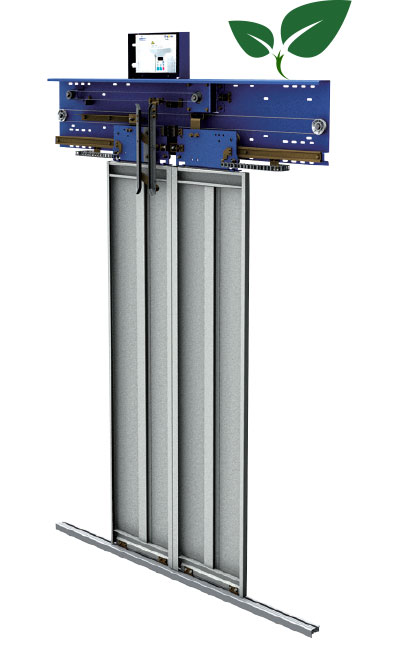

○ Permanent magnet synchronous motor frequency conversion driven door machine system, with low speed, high efficiency, constant torque, high control precision, low noise,Small vibration, maintenance free;

○ Door motor adopts permanent magnet synchronous motor, which has the characteristics of compact structure, low speed, large torque, high efficiency, low operating noise, small vibration and long service life;

○The arc tooth synchronous belt drive has the characteristics of high transmission efficiency, smooth transmission, high transmission accuracy, low noise and simple structure;

○ The use of upper and lower keeping device, prevent the door from its guide device, to avoid human causes of falling into the well danger;

○ Door safety protection device, the use of advanced light curtain, open and close the whole cross light scanning, without external controller, with good electromagnetic compatibility and anti light interference;

○ More than 8 million times of opening and closing tests and hall door system impact test certification, to ensure the safety, stable and reliable operation of the elevator door system.

You can take the elevator by swiping the card through the non-contact card reader set in the elevator car or the entrance floor

Method of use

①Select the upstream and downstream buttons on the floor of the car entrance.

② Enter the elevator car.

④ Arriving at the destination floor passengers leave the car, the elevator continues to wait according to the system distribution.

④ Arriving at the destination floor passengers leave the car, the elevator continues to wait according to the system distribution.

English

English  简体中文(中国)

简体中文(中国)  Español

Español  Русский

Русский